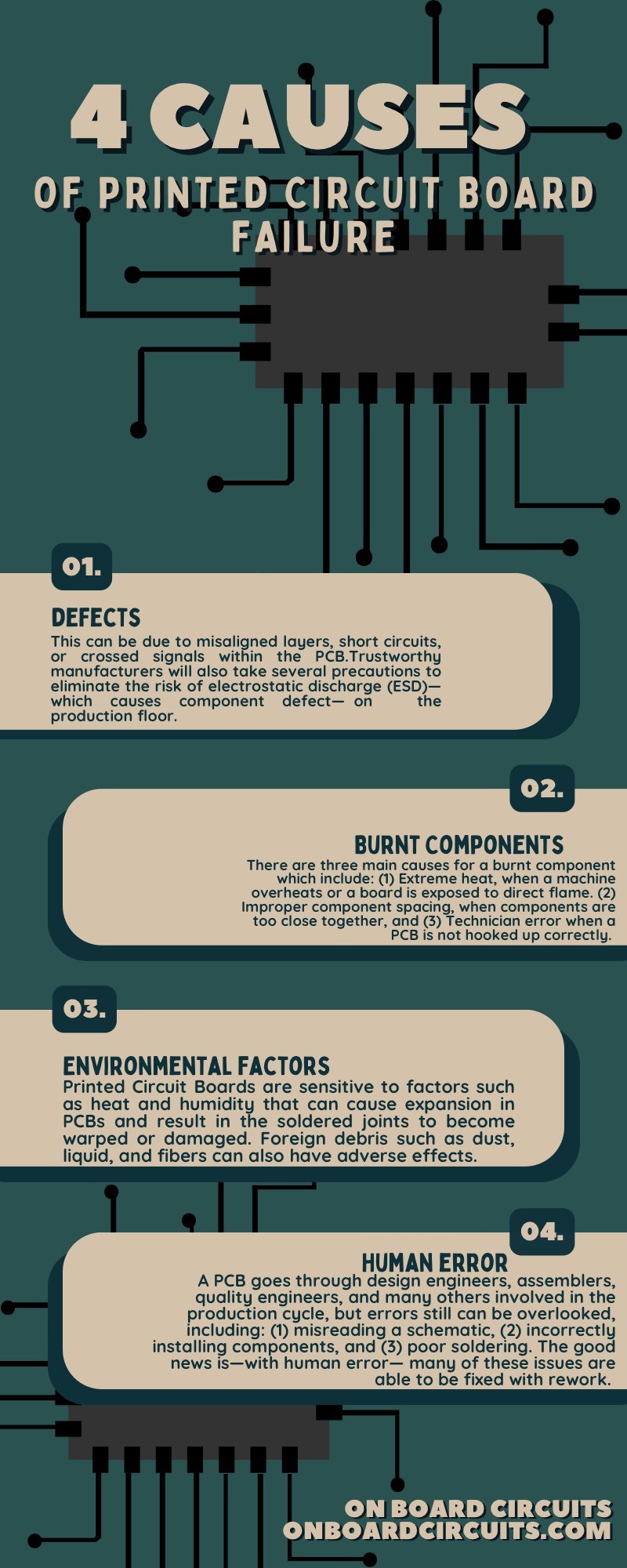

Printed circuit board failure doesn’t happen very often, but when they do, they’re typically caused by one of 4 reasons. We’ll touch on these four causes below. Be sure to check out our infographic at the end of the article for an illustration of these causes too!

Defects

There are a number of defects in a PCB that can cause board failure. Some of these defects include misaligned layers on the PCB, short circuits, or crossed signals on the board. All of these defects are avoidable if using a reputable manufacturer. Working with a company like OnBoard Circuits can help companies avoid such issues. With current supply shortages, it’s more important than ever to work with a resource dedicated to providing you with a functional, non-defective PCB.

Burnt components

Burnt components are a very real cause of defective PCBs. What causes burnt components? Extreme heat is one of the more common causes, whether it’s due to extreme heat exposure or a machine overheating and causing components to burn. If components are spaced too close together, that can also result in burnt components. Even when properly designed, if a technician improperly hooks up a PCB, burning can result.

Environmental factors

For being tough workhorses, PCBs are also pretty sensitive to a number of environmental factors. As mentioned above, one of those is extreme heat. Extreme cold and moisture can also do a number on printed circuit boards. Foreign substances such as dirt, dust, or fiber also negatively impact a PCB.

Human error

Several of the defect causes listed above really boil down to human error. Keep in mind that when a printed circuit board is being built, it goes through the hands of numerous people, including design engineers, assemblers, quality engineers, as well as those involved in production; many opportunities to negatively impact a PCB if care is not taken. Problems in PCB designs can cause failure to occur. Quality control in particular can overlook issues such as incorrect schematics, incorrectly installed components, or poor soldering, which can cause the failure of a PCB.

With current challenges in the industry, it’s more important than ever to avoid issues causing printed circuit board failure. Work with a professional, reputable PCB company to get PCBs that will suit your needs reliably every time!